James Muirhead opened the large envelope, stamped ‘DO NOT BEND’, that he’d just been handed by a senior car interior designer.

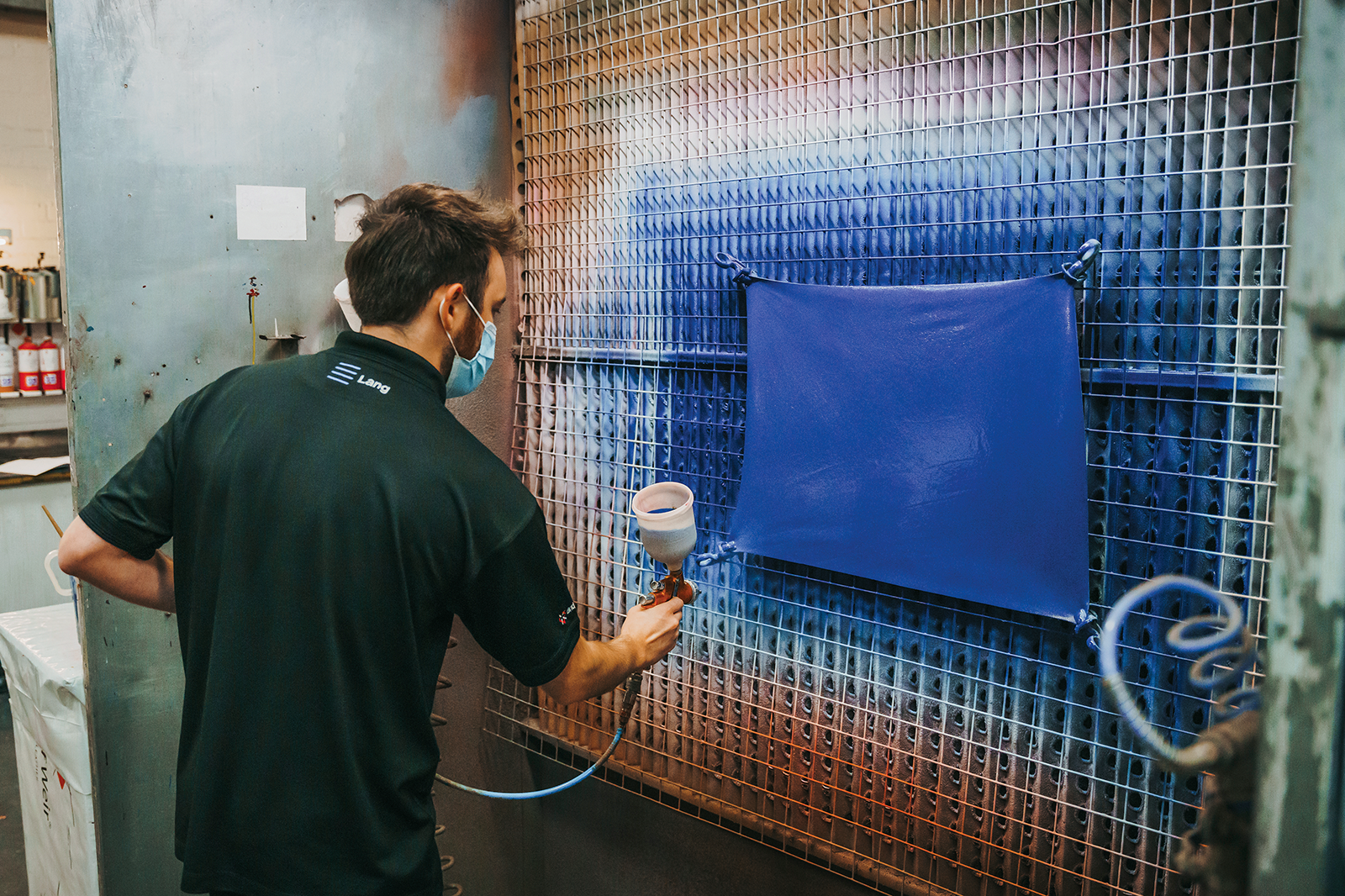

Inside was a rock, a piece of seatbelt, a length of thread and other random oddities. The gauntlet cast down was to match the colour of each item in leather.

A couple of weeks later, every one of the perfectly colour-matched samples was returned, including one of the envelope itself, stamped ‘DO NOT BEND’.

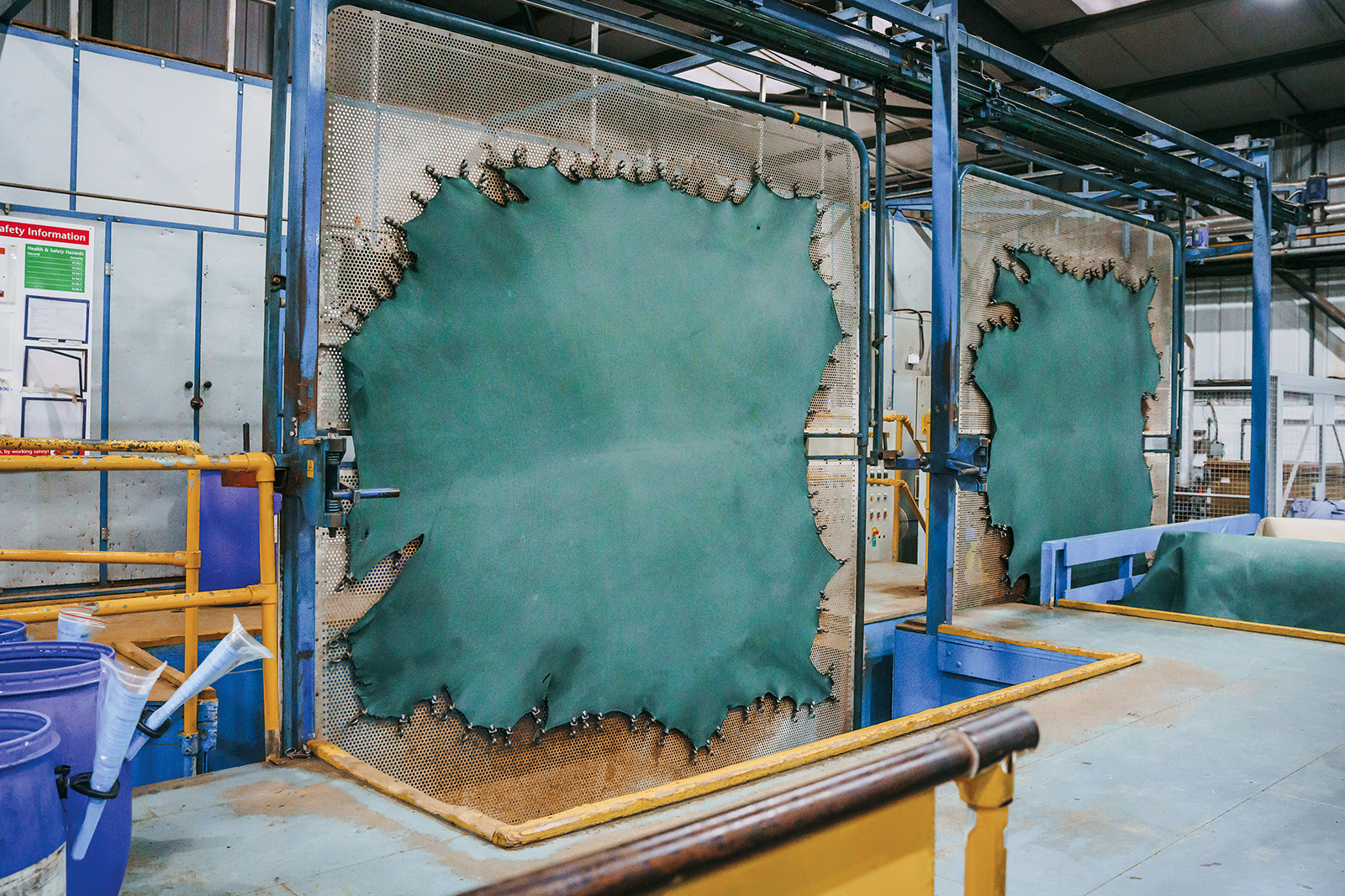

Machines play vital roles today, but this remains an artisanal industry

Bridge of Weir has a legacy of meeting tough demands.

When the seminal Ford Model T was in the offing, company founder Arthur Muirhead, James’ great-great-grandfather, went to the USA and convinced Henry Ford to choose his leather for the seat upholstery.

The first Model T plant built outside the USA was opened in Trafford, near Manchester, in 1911, and the cars were indeed trimmed with leather from Renfrewshire.

Technological advances have kept Bridge of Weir Leather at the cutting edge of automotive trimming