We’re on the outskirts of Warwick, in a compound filled with huge metal blocks piled to twice head height and streaked with rust.

Each block has a serial number, but a few carry great names of British motoring: Jaguar, Triumph, MG, Rover.

These are press tools, used for making panels back in the day and employed today by British Motor Heritage to make them again. This collection has been amassed over many years.

Our guides are British Motor Heritage managing director Graham Payne and Iain Taylor, general manager of BMH’s panel-pressing partner Taylor Pressform.

Graham Payne (on right, with Iain Taylor) is focusing on future-proofing British Motor Heritage’s business

These two companies make the body bits that keep MGBs and MGFs, Spitfires, Morris Minors, Minis and classic Range Rovers on the road.

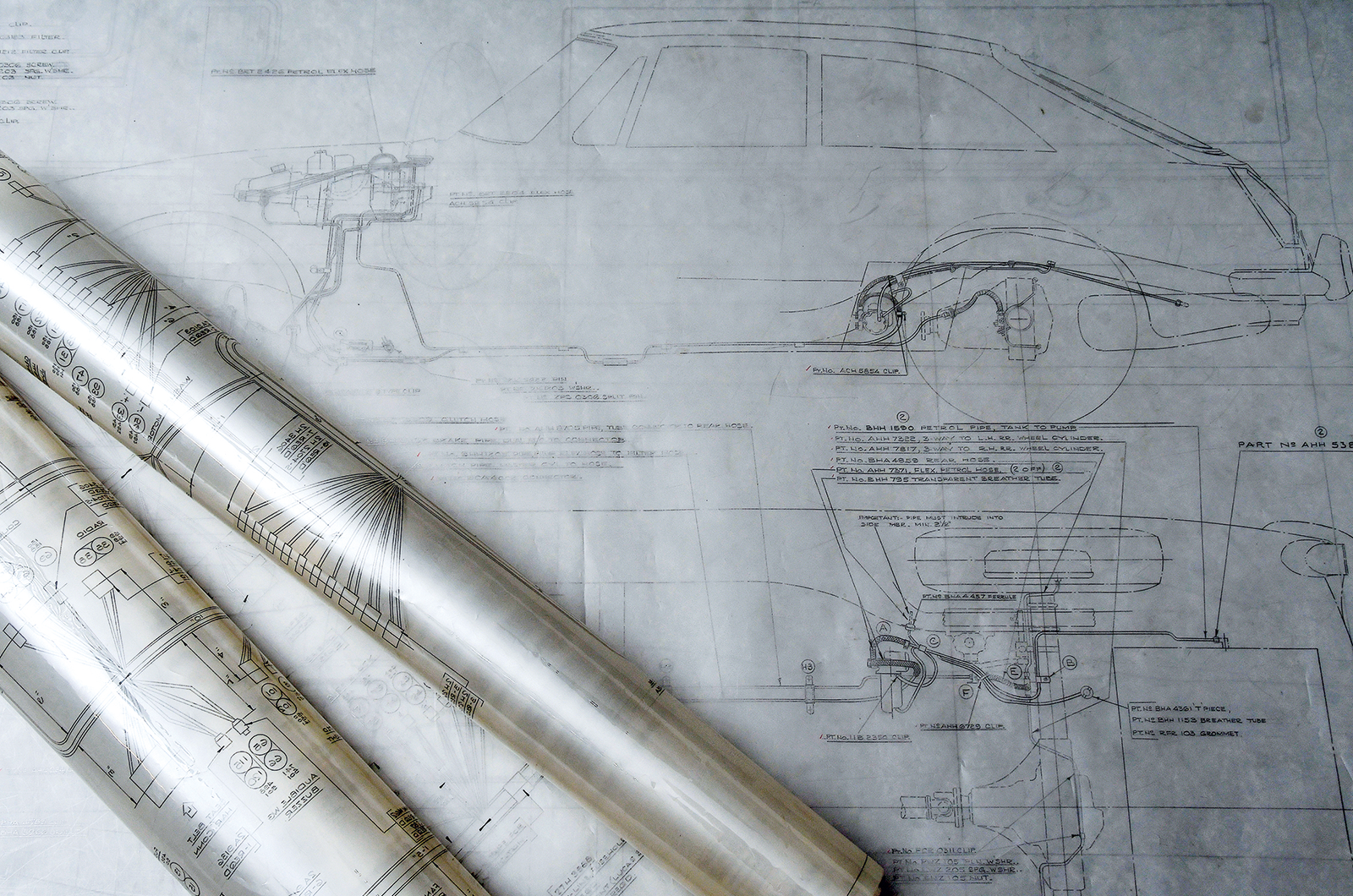

Also here is a mind-blowing cache of historic blueprints and documents BMH has inherited and is now beginning to digitise.

Payne estimates there are one million pieces in all, some a century old.

A recent extraordinary find is a plan of Rover’s Solihull factory site so early it reveals details of the workshops used for automotive jet-engine research in the 1940s.

The huge document archive at British Motor Heritage is being digitised