Starting out as a small automotive accessory shop in the Dorset town of Bridport in 1984, Top Gear was an early adopter of online retailing, selling alloy wheels, tyres and, eventually, a range of custom exhausts, under the name Longlife.

Today, Longlife is the UK’s leading supplier and manufacturer of bespoke stainless-steel exhaust systems, with a network of 29 franchised dealers across the British Isles.

“In the past we’ve been heavily involved in the performance and prestige car market,” says director Kevin Page-Smith, “but classic cars are a real growth area for our company.”

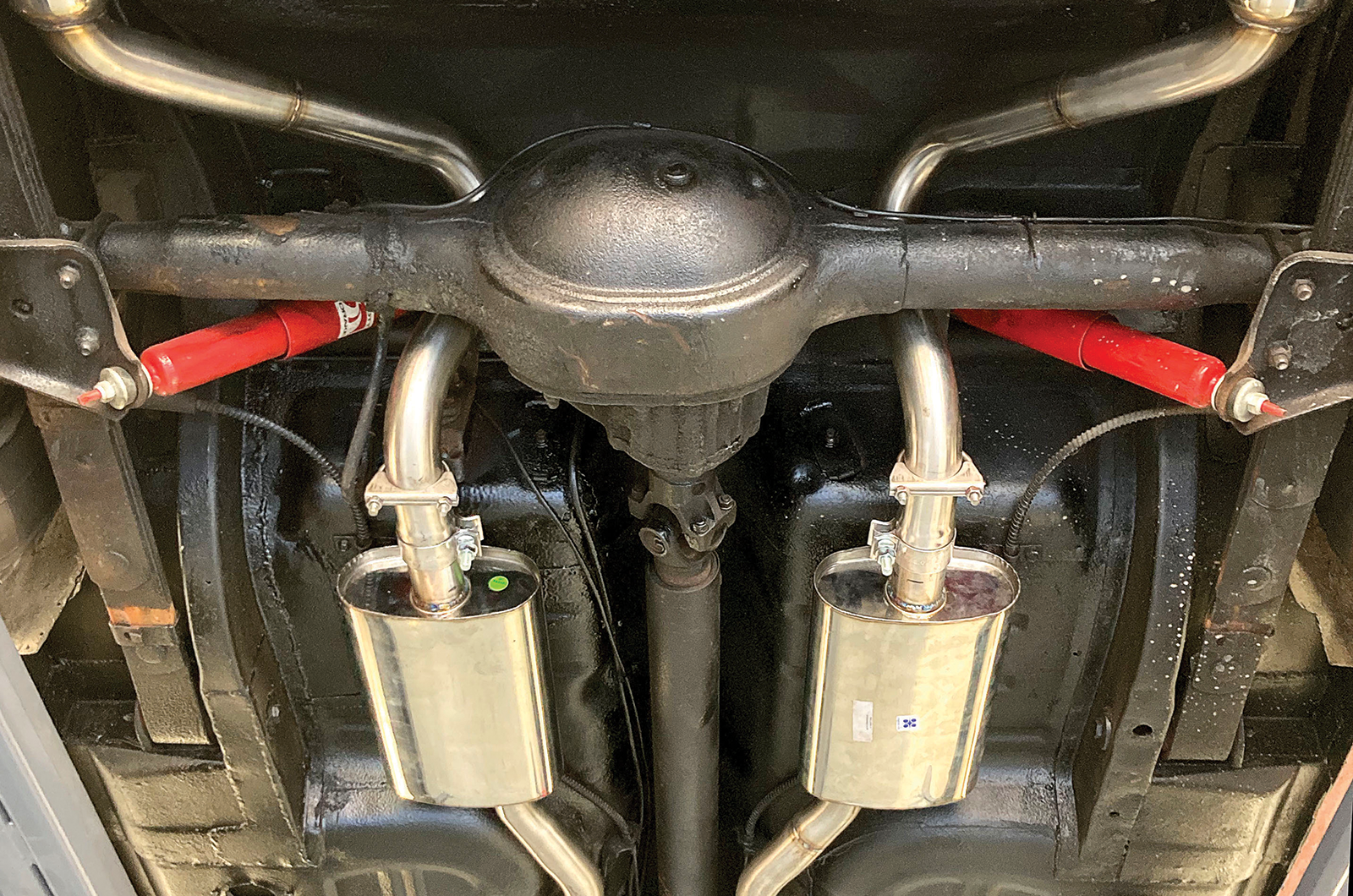

Clockwise from top: the exhaust system is cut off over the axle; pipes can be drawn by machine to help form joints specific to the car; pieces are bent to shape